Rack-Way Production and Delivery is an additional module for Production and for Shipping. Starting from the order indicating what glass items are to be placed on the shipping racks, the Rack-Way Delivery module allows you to organize the entire production by using a set of intermediate racks (called production racks) to obtain the desired results. Used Delivery Racks are included in the Packing List, so the detailed allocation of each rack is known.

Once the main fabrication list is assigned, the Rack-Way specific sequence-maintaining optimization add-on, let you achieve the best optimization results with the smallest amount of “A Racks” or “L Racks” space around the break-out table without any additional manual sorting needs. Rack-Way reduces manual sorting, thus increasing productivity and quality. Highly recommended for IG Manufacturers. Also useful for Harp-Racks.

Functionality

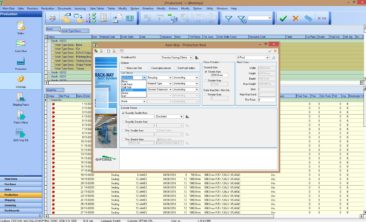

- Sequence-maintaining optimization algorithm

- Supports different restrictions to optimize without re-sorting on the break-out area

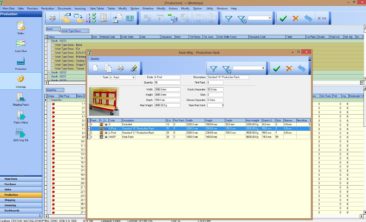

- Management of traditional A-frame, L-frame and Harp Racks

- Definition physical characteristics of each rack type

- Grouping and Sorting criteria function for items listed on the batch

- Ascending or Descending Sorting Directions

- Quantity and Size Exception Management

- IG Assembling sequence creation for Automatic IG Lines

- Spacer bending sequence creation for Spacer Bender

- Maximum quantity or depth value per type of rack

- Printout of Rack List and Detailed Stack List

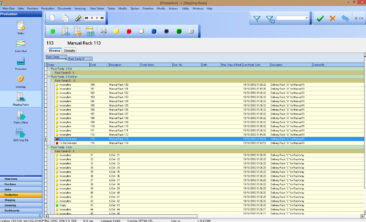

- Rack No. and Position assignment for Edit-Way, TV-Way and Re-OPT display

- Manual Loading Sequence trough GMC-Way Monitor Tracking Tool (GMC-Way Monitor Option)

- Detailed Rack Status and Real-time Loading Sequence

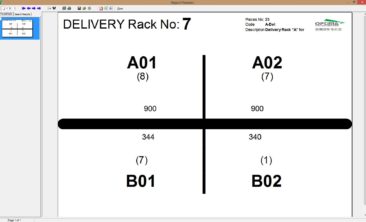

- Delivery Rack Allocation Overview

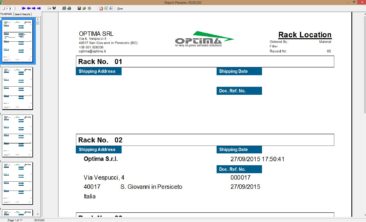

- Packing List creation from Delivery Rack

- Delivery Rack assignment to Delivery Note / Invoice

- Delivery Rack Invoicing, according to settings, if racks are not returned